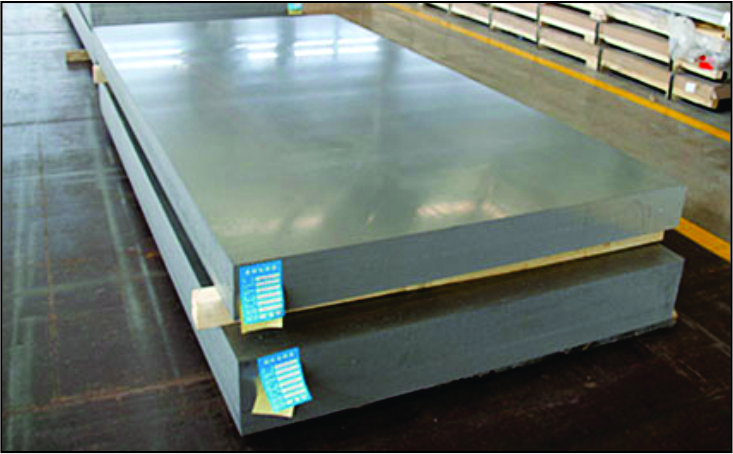

7050 Aluminum Sheet

- Thickness: 8-200 mm

Properties of 7050 Aluminum Sheet

Zn is the mainly alloy elements of 7050 aluminum sheet. Adding magnesium into the 7050 alloy which contains 3% -75% of Zn forms a significant strengthening effect of Mg Zn 2 and makes the effect of heat treatment far better than Al-Zn binary alloy. 7050 aluminum sheet is mainly used in aerospace, mold processing, machinery and equipment, fixture, particularly high aircraft structures and other requirements of strength, corrosion resistance and strong high-stress structure.

| Alloy | Temper | Thickness(mm) | Width(mm) | Length(mm) | Typical products |

| 7050 aluminum sheet | O、T6、T651、T7451 | 8-200 | <1500 | <8000 | Golf head, mold, aircraft landing gear and other |

Features and Applications of 7050 Aluminum Sheet

7050 aluminum sheet is mainly used in the aerospace industry, mold processing such as blow molding (bottles) mode, ultrasonic plastic welding mold, golf head, shoe mold, paper and plastic molding, foam molding, lost wax mold, templates, fixtures, machinery and equipment, and the production of high-end aluminum bicycle frame.

Specifications of our Assortment:

Alloy | Temper | Width(MM) | Thickness |

1050, 1060, 1070, 1080, 1100 | F,O | 1500 mm (mix) | 6 to 200 mm |

2011, 2014, 2024 | T4, T6, 0, T3, T3510, T3511, T8, T8510, T8511 | 1500 mm (mix) | 6 to 200 mm |

3033, 3103, 3003 | F, O | 1500 mm (mix) | 6 to 200 mm |

40433, 4047 | F, O | 1500 mm (mix) | 6 to 200 mm |

5005, 5052, 5086, 5083, 5056 | F, O | 1500 mm (mix) | 6 to 200 mm |

6061, 6063, 6082 | O, F, T4, T5, T6, T66 | 1500 mm (mix) | 6 to 200 mm |

7075 | O, F, T4, T6 | 1500 mm (mix) | 6 to 200 mm |

8011 | O | 1500 mm (mix) | 6 to 200 mm |